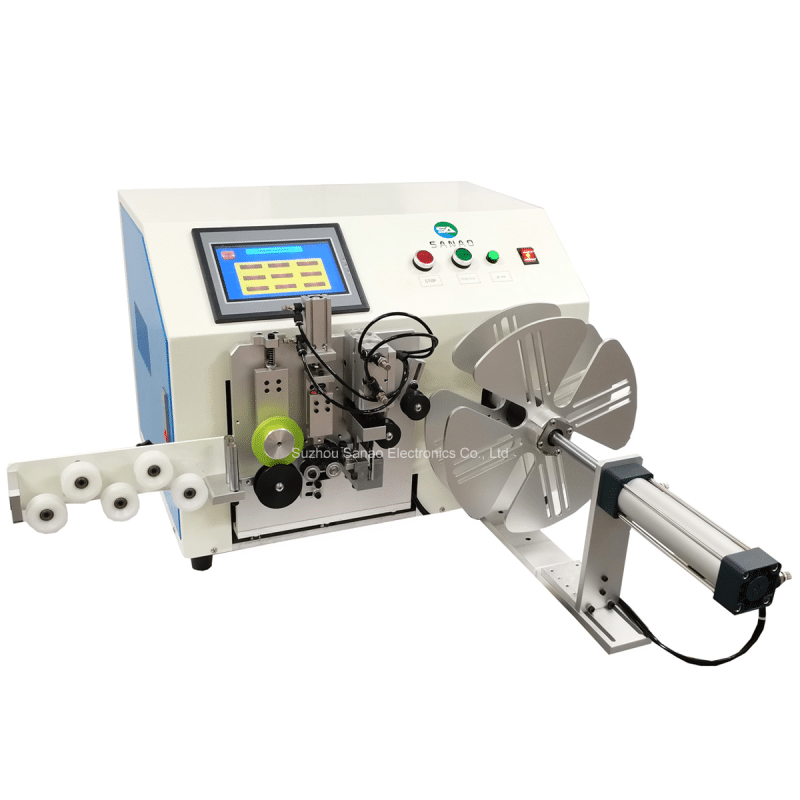

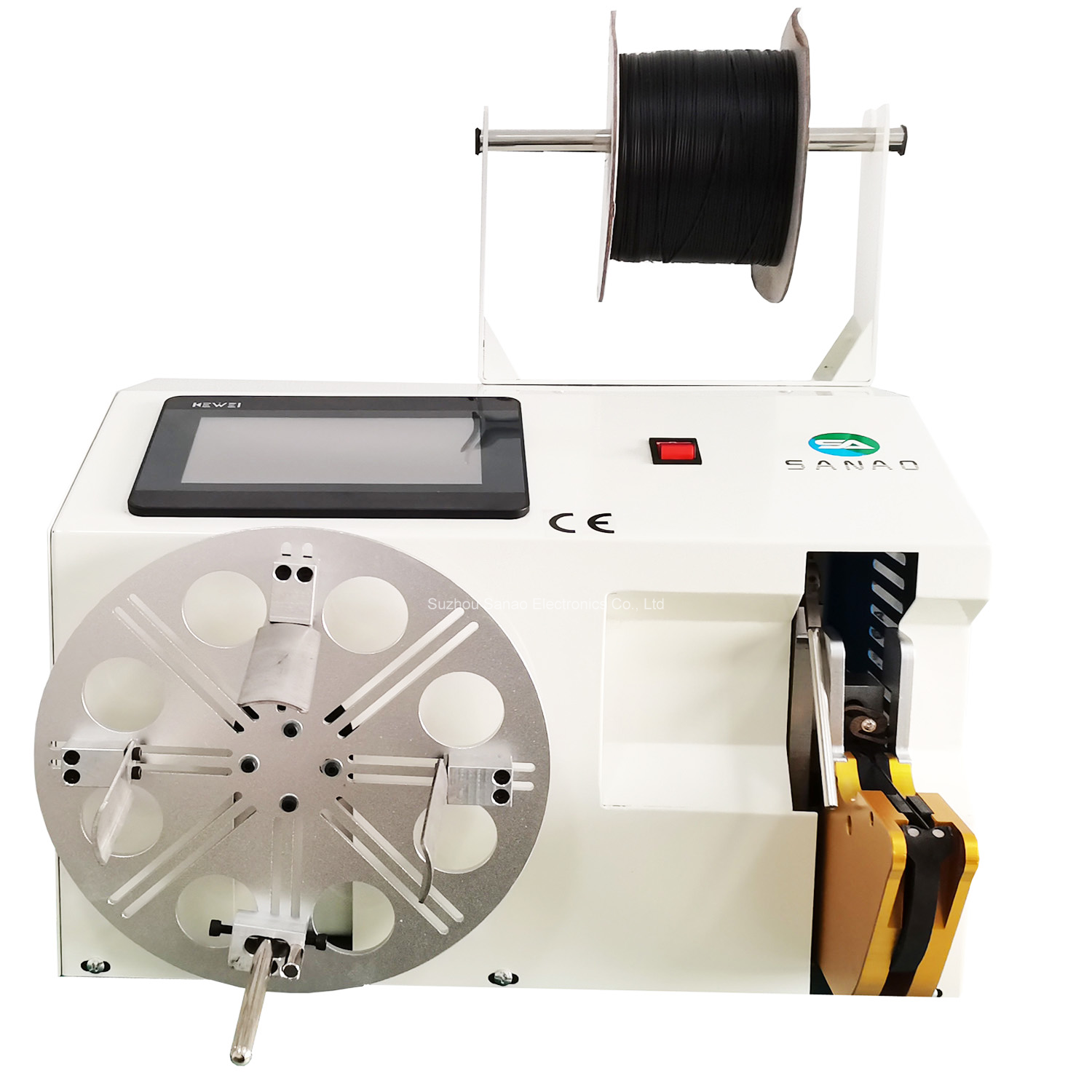

2022 Latest Design Sheathed Wire Cutting And Stripping Machine - Semi-Automatic Cable Coil winding bundling Machine – Sanao

2022 Latest Design Sheathed Wire Cutting And Stripping Machine - Semi-Automatic Cable Coil winding bundling Machine – Sanao Detail:

Product Video

Product Introduction

SA-F02 This machine suitable for winding tying AC power cable, DC power core, USB data wire, video line, HDMI high-definition line and other transmission lines, This machine haven’t the bundling function, Coil diameter is Adjustable from 50-200mm. One machine can coil 8 and round both shape, coil speed and coil circles can directly setting on machine, It’s Greatly Improved wire process speed and save labor cost.

Advantage

1.Automatically sensing to tie;

2.Feasible to adjust winding speed, winding circles.

3.Automatically output counting;

4.Saving labor cost;

5.Visual human-computer interface and easy to operate;

6.Automatically feeding for tying line;

7.Low cost and high efficiency.

Products Parameter

| Model | SA-F02 |

| Name | Flat cable winding machine |

| Power Supply | AC220V±10% 50Hz/60Hz |

| Power Rating | 100W |

| Winding Speed | 2-8circles/s,adjustable |

| Winding Diameter | 50.0~200.0mm |

| Winding Shape | “8″ shape,circle |

Product detail pictures:

Related Product Guide:

We take pleasure in an extremely fantastic standing among the our prospects for our great product top quality, competitive cost and the finest support for 2022 Latest Design Sheathed Wire Cutting And Stripping Machine - Semi-Automatic Cable Coil winding bundling Machine – Sanao , The product will supply to all over the world, such as: Namibia , Palestine , Singapore , We hope to have long-term cooperation relationships with our clients. If you are interested in any of our products, please do not hesitate to send enquiry to us/company name. We ensure that you can be totally satisfied with our best solutions!

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.

Write your message here and send it to us