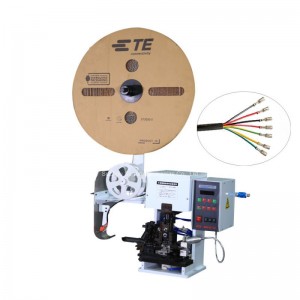

Fully Automatic Heavy Duty Wire Stripping Machine

| Model | SA-CW1500 |

| Capability | Up to 3-layer shield cable |

| Wire material | Wide range of industrial wires |

| Conductor cross-section | 6 - 150 mm² |

| Cutting length | 1 - 100,000 mm (can be customized) |

| Cutting length tolerance | < 0.002 * L |

| Stripping length (side I) | 0 - 500 mm |

| Stripping length (side II) | 0 - 250 mm |

| Maximum guide tube diameter | 32 mm |

| Driving mode | 28-roller with belts driving |

| Display mode | 7-inch touch screen |

| Memory capacity | 100 materials |

| Blade material | High speed steel |

| Productivity | 1000 - 1500 pcs./h |

| Power supply | 110, 220 V (50 - 60 Hz) |

| Power | 1200 W |

| Weight | 270 kg |

| Dimension | 1180 * 650 * 1200 mm |

Write your message here and send it to us